We use a custom-built piston & cylinder apparatus

for pressing pills of defined geometries.

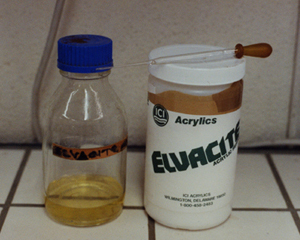

As a binder, we use Elvacite polymer resin, dissolved in acetone.

|

|

|

||

| Laboratory scale for weighing aproximateely 10 g of sample powder in a glass beaker | Manual homogenization of sample powder with Elvacite resin (dissolved in acetone). |

Student slowly releasing pressure device (ENERPAC, with hydraulic hand pump) from 450 bar to ambient pressure. | ||

Powder pills are produced by pressing the rock powder under a maximum pressure of 450 bar. Before pressing, an acrylic polymer resin is added in order to have the individual grains stick together. It is dissolved in acetone (polymerizes quickly in water), which vaporizes and leaves a grain-coated coagulate of grains behind. Under pressure, it flows into one mass and binds the grains together. Once the pressure is released, it solidifies and the result is a solid pill that can easily be measured in the XRF spectrometer. An earlier version used polyvinyl alcohol instead (much more toxic). Make sure to have read the material safety data sheets (MSDS) before using it. You can download them from the safety page.

1. Dry the powder overnight in an oven at 110°C

2. Weigh ca. 10 g dry powder in a 150 ml beaker

3. Add a 2/3 pipette of 10% Elvacite (dissolved in acetone)

4. With a thick glass rod, stir until the powder appears to dust out of the beaker

5. Repeat twice, then add 1/3 pipette and repeat twice. Total: 2.3 pipettes (2 mL)

6. Fill the dry powder into the pressing equipment, don't stir, but distribute equally while pouring. Make sure the piston is right side up (polished side down).

7. Insert equipment into hydraulic press and apply pressure (350 to 450 bar)

8. Leave for one minute, NOT longer!

9. Release pressure slowly by opening the release handle

10. Securely grab the device at bottom and top, turn upside down slowly, secure piston

11. Take bottom plate off. Careful: don't drop piston. Cover cylinder piece bottom with plastic cap. Turn right side up again and re-insert into hydraulic press.

12. Slowly, by hand, press the piston down into the cylinder to press the pill out of it and into the plastic cup (press by turning the top wheel of the press). Hold the piston with two fingers while doing so (you feel it releasing), and stop applying pressure as soon as the pill is released, otherwise it will break.

13. Remove assembly and carefully drop the pill onto a clean paper towel.

CRASH-TEST: The pill gets dropped onto a stainless steel surface inside the x-ray spectrometer and may brake if it was not made well. To simulate and test its behaviour, drop it from 8 cm high on a double paper towel. It should neither break nor have cracks. If so, grind it in the agate mortar/pestle and add another 1/3 mL Elvacite, try again.

The assistants perform crash tests with some of the pills to ensure that they were tested. If a pill breaks in the XRF spectrometer, it has to be taken apart and cleaned which takes ½ day.